Necessary Tips for Cleaning Carpets at Home

The role of the Inanlu and Bharlu clans in Persian nomadic handlooms

Undoubtedly, during the weaving of any carpet, problems may arise, but by observing some essential and critical points, acceptable quality can be achieved. However, neglecting these points can lead to irreparable damage to the carpet, making it unsuitable for presentation. One of the first essential points in carpet weaving is the presence of a flawless and faultless loom.

Before performing the warp winding, the loom carpet must be thoroughly examined to ensure its soundness. It should be determined that the upper and lower looms are parallel and perpendicular to the weft, with no excess protrusions. After checking the loom, it’s time to perform a proper and uniform warp winding, which is crucial for the final quality of the carpet—usually, the thread used as the warp is made of cotton and is white. However, in some areas, especially among nomads, wool is prevalent, and occasionally, silk thread may also be used as a warp.

The most critical points in warp winding during carpet weaving:

- One of the most essential aspects of warp winding is to ensure that it is done perfectly in the center of the loom, ensuring symmetry on both sides so that the weight of the warp does not shift to one side.

- The tension of warp threads across the entire width of the loom should be uniform and equal. To achieve this, it’s recommended to perform warp winding at a specific time in succession to avoid interruptions.

- Since the distance between warp threads usually equals the diameter of the weft used, ensure that 4 to 5 lines are typically pulled within each centimeter.

- Warp winding should not be done with excessive tension. For better quality, it should be done with moderate and proportionate pressure. Therefore, if you lack sufficient experience, it’s better to entrust it to a specialist.

- Another critical point in warp winding is to check the evenness of the number of threads pulled. If you have correctly passed the warp thread under the loom at the beginning, you should also pass it over at the end to ensure that the warps are even or paired.

After the warp-winding stage, the next step is knotting. Essentially, this is securing the ends of the weft threads to make the knots smooth and stable. After twisting, the chain weaving or “birdman” begins, which ensures that the lots of the carpet do not separate or tear when used.

One of the most critical factors for successful weaving is precision in pulling the thin weft thread. Therefore, it’s essential to ensure this before starting the weaving process. Remember that the quality of carpet weaving is more related to the quality of pulling the thin weft thread than anything else.

It’s worth noting that all these stages require expertise and skill. Therefore, if you want the final quality of the carpet to be high, it’s better to have these stages performed by experienced individuals when necessary.

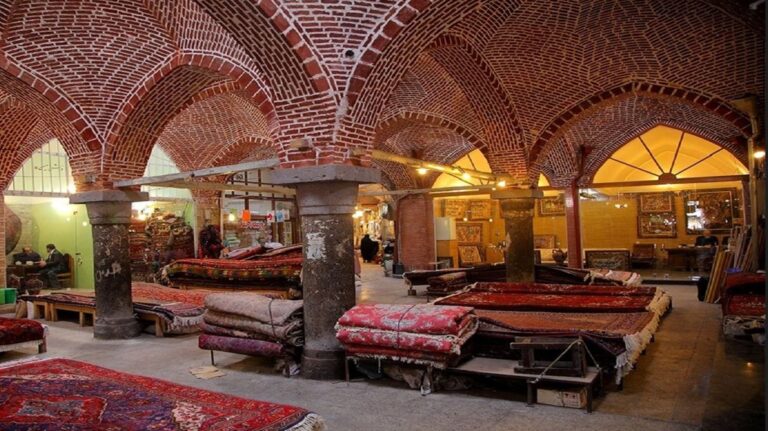

(Carpet Loom)

Precise Control of Carpet Height

To prevent issues and defects that may arise due to a lack of control over dimensions, it is advisable to periodically, ideally after each row, adjust the carpet height in proportion to the calculated row count and then check it within the fabric. Setting the carpet height correctly from the beginning will prevent many problems. However, you may still encounter issues during weaving, such as low or high spots, which will be explained further.

If you notice severe low spots during your work, consider the following points:

- You may have beaten the weft too firmly and excessively. Always remember to maintain the appropriate pressure when using the beater.

- You may have forgotten to use thick and thin weft threads in each row regularly.

- Over-tightening the loops with top roller looms or excessive stretching beyond the standard tension can also lead to this issue.

Sometimes, you may also face problems with high spots during carpet weaving. In such cases, it’s essential to be aware of the following:

- You might have beaten the weft gently and less than the standard.

- Looseness in the pile can also result in high spots. To rectify this issue, you can tighten them evenly using top roller looms.

- If you’ve pulled the thin weft too tightly and dried, no matter how much you beat it, the next row won’t reach the sufficient and standard height, resulting in high spots in the fabric.

- Excessive pile density is another reason for high spots in the fabric.

It’s important to note that while it’s better to prevent low or high spots by considering essential factors in carpet weaving if you encounter these issues, the worst decision is to shorten or lengthen the remaining carpet excessively. Therefore, weaving the remaining rug according to standard size measurements is better if you face such situations.

Another critical point is always to use standard knots of three centimeters to prevent thread shortages. Sometimes, continuing the carpet weaving becomes impossible due to this issue, losing your efforts.

Lastly, comb the knots with your two fingers after weaving each row to ensure they are perfectly smooth and tight within the carpet structure. Additionally, you can use the beater to search the knots. Remember that searching the fabric with the beater is essential for carpets intended for raised work.